|

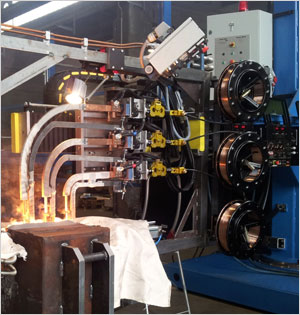

Electroslag welding (ESW) is a highly productive, single pass welding process for thick (greater than 25 mm up to about 300 mm) materials in a vertical or close to vertical position. (ESW). An electric arc is initially struck by wire that is fed into the desired weld location and then flux is added. Additional flux is added until the molten slag, reaching the tip of the electrode, extinguishes the arc.

The wire and tube then move up along the workpiece while a copper retaining shoe that was put into place before starting (water-cooled) is used to keep the weld between the plates that are being welded. Electroslag welding is used mainly to join low carbon steel plates and/or sections that are very thick.

We produce up to 3 torches in same line to reduce the welding time with high quality control system

|

|